Manufacturing and logistics of your plastic parts

With its upstream validation and development, iP3 manages the production and logistics of your products, and ensures the manufacture of plastic parts, including external decorative parts and technical parts. We have a choice of production sites to suit the specification of your products and their delivery locations.

In terms of logistics, our goal is to maintain a customer service rate as close as possible to 100%.

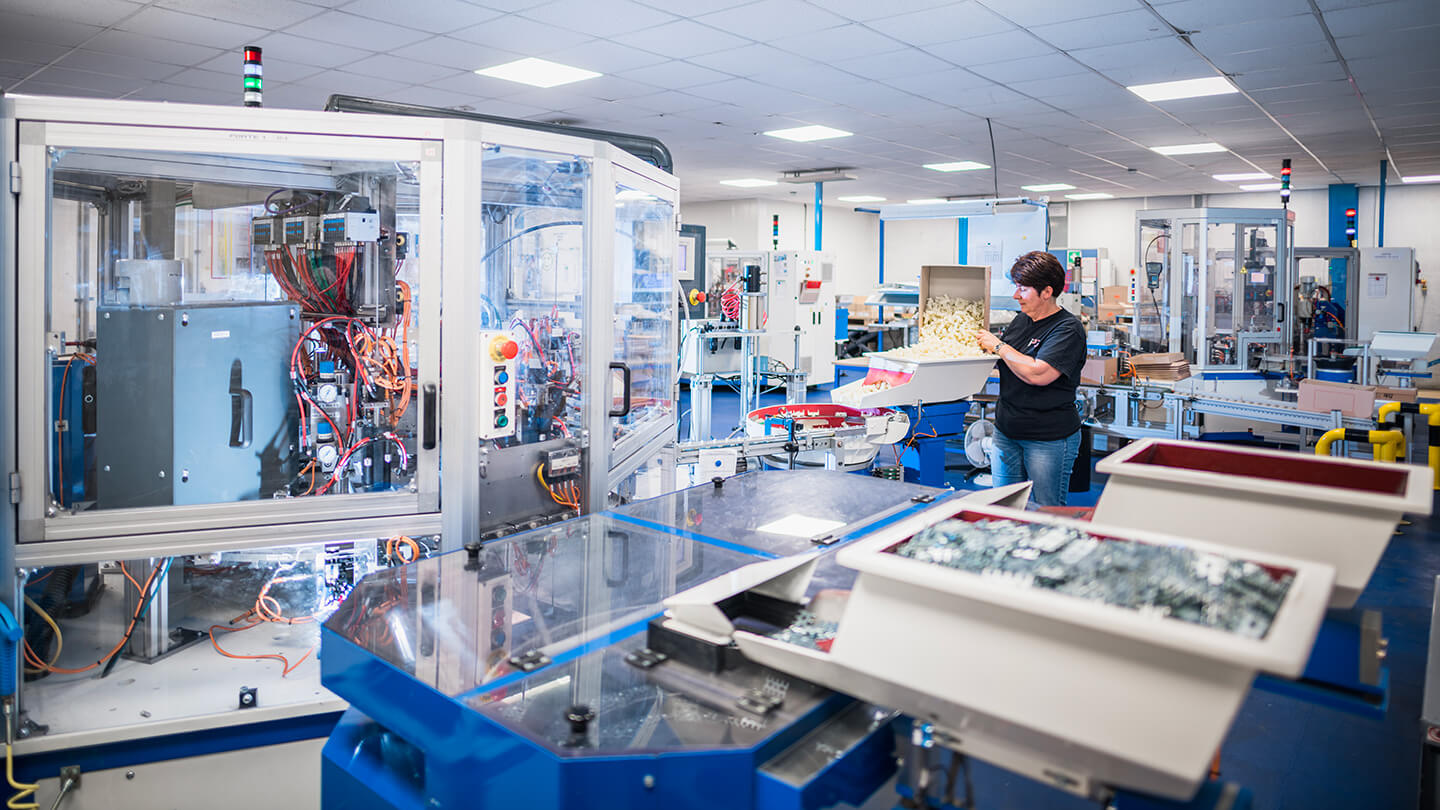

Production

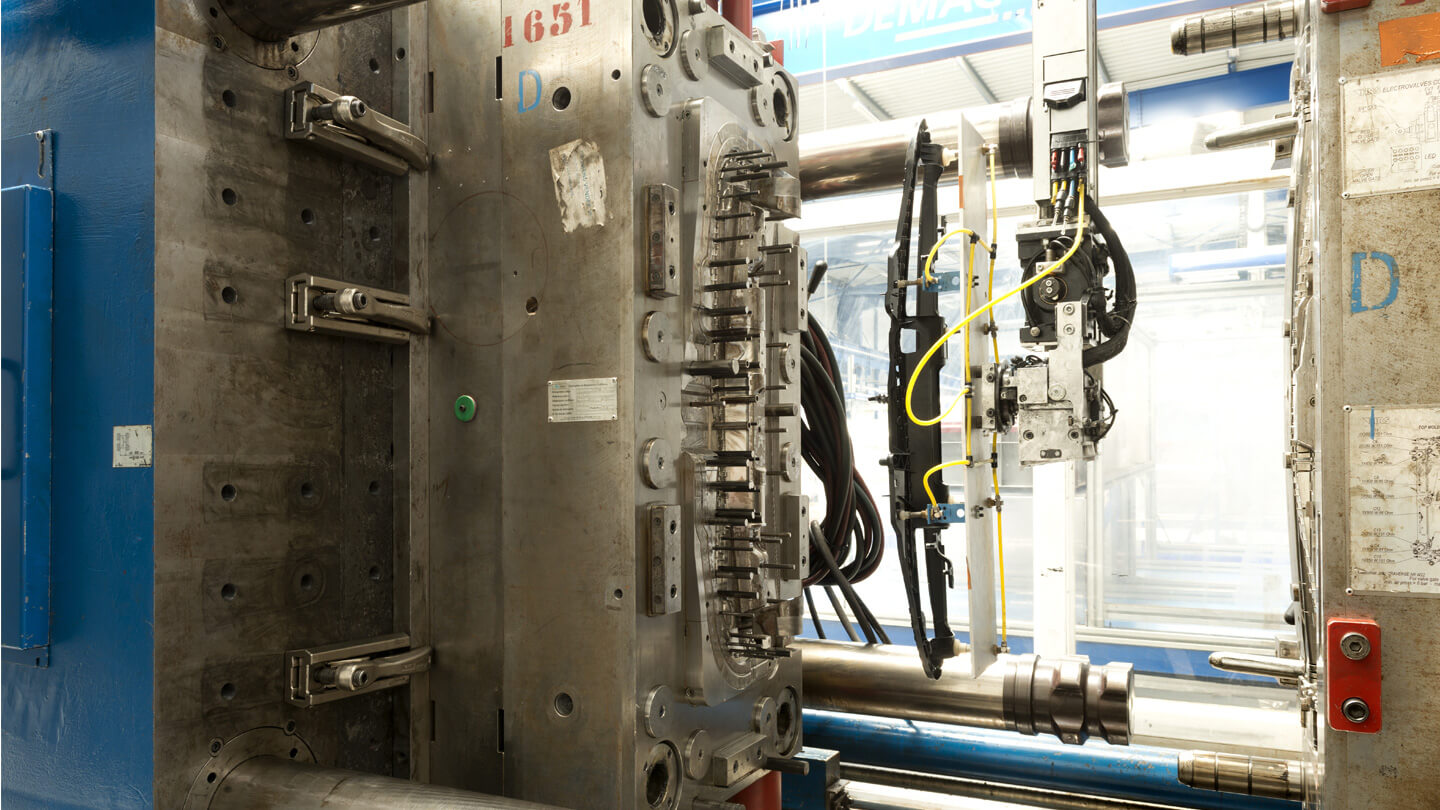

As experts in plastic injection moulding (thermoset and thermoplastic), we have built our technical knowledge around medium to large production runs of parts ranging from 1g to 6kg. With our experience in the industrialization of safety parts, we have a full range of technological solutions to meet our clients’ needs:

- Bearing cage specialist

- Insert molding

- Component overmoulding

- Bi-material injection

- Gas injection

- Pad printing

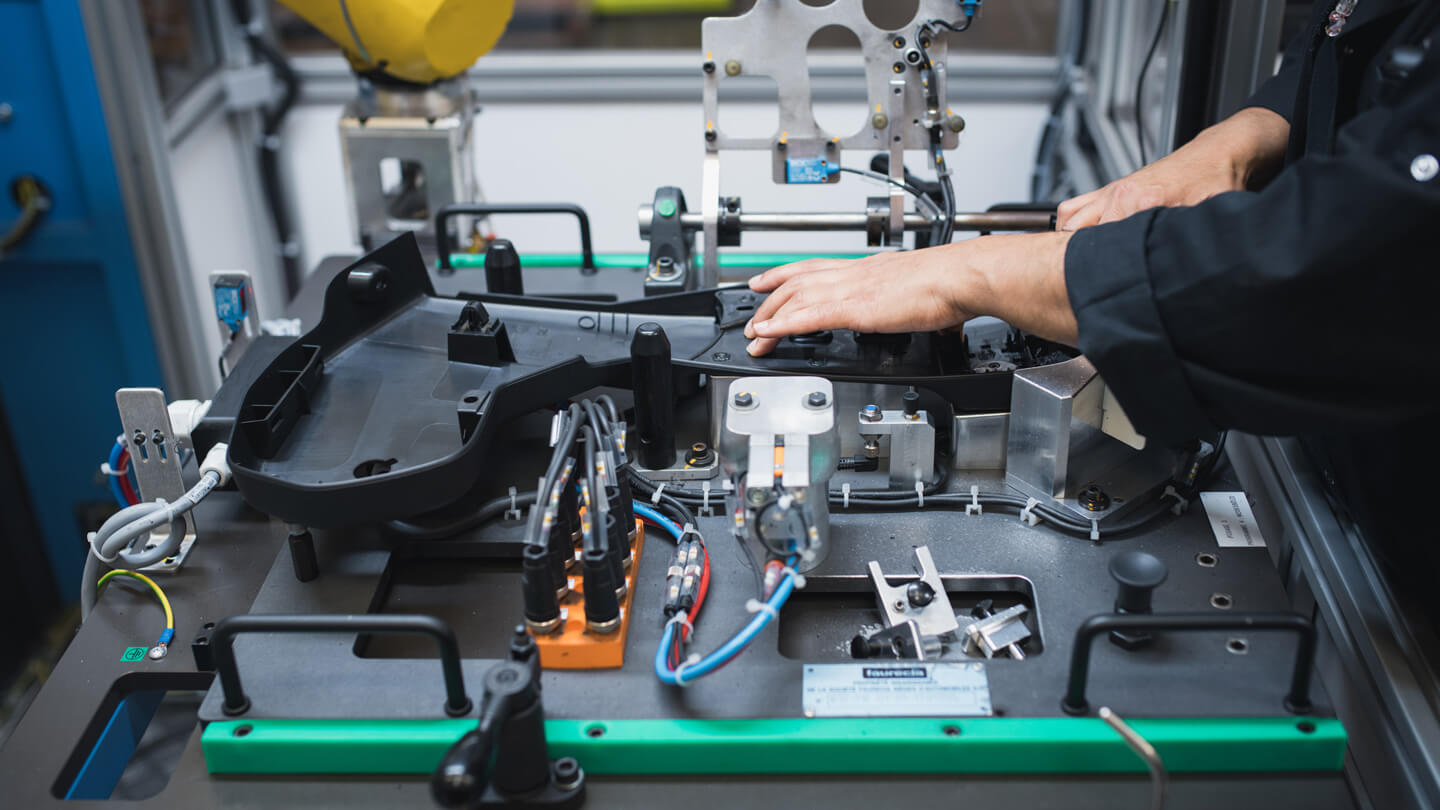

- Manual and automatic assembly

- Ultrasound or mirror welding

- Laser engraving

- Fine wall injection

- Thermoset injection (BMC-phenolic)

Production of decorative and technical parts

- More than 70 thermoplastic injection machines

- 4 thermoset injection machines

Assembly machines

- 2 units with 6-axis robotics

- 4 automated lines

- 4 capacity bases for semi-automated assembly

- 2 bases for automatic overmoulding of metal inserts

Decoration

- 2 pad printing machines

- 1 laser engraving machine

Ask us for information

Contact us